Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: ACP

Brand: Amrta or OEM

Type: Water-Cooled

Cooling Method: Water-cooled

Unit Structure: Integral

Selected Voltage: 380V/50HZ

Noise Level: Low

Certification: CE

Condition: New

Refrigerant: R134a/R407c/R410a

Compressor: Centrifugal Compressor

Evaporator: Flooded / Falling-Film

Condenser: Shell And Tube

Application Fields: Food Processing,Printing,pharmaceutical,Plastic,Chemical,Laser

Cooling And Heating: Cooling / Heating

Cooling Mode: Refrigerant Spray Cooling

Control: Siemens Microcomputer

Packaging: Plastic Film Wrapped

Productivity: 2000Sets/Year

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 200Sets/Month

Port: Qingdao,Shandong,China

Payment Type: L/C,T/T,Western Union

Incoterm: FOB

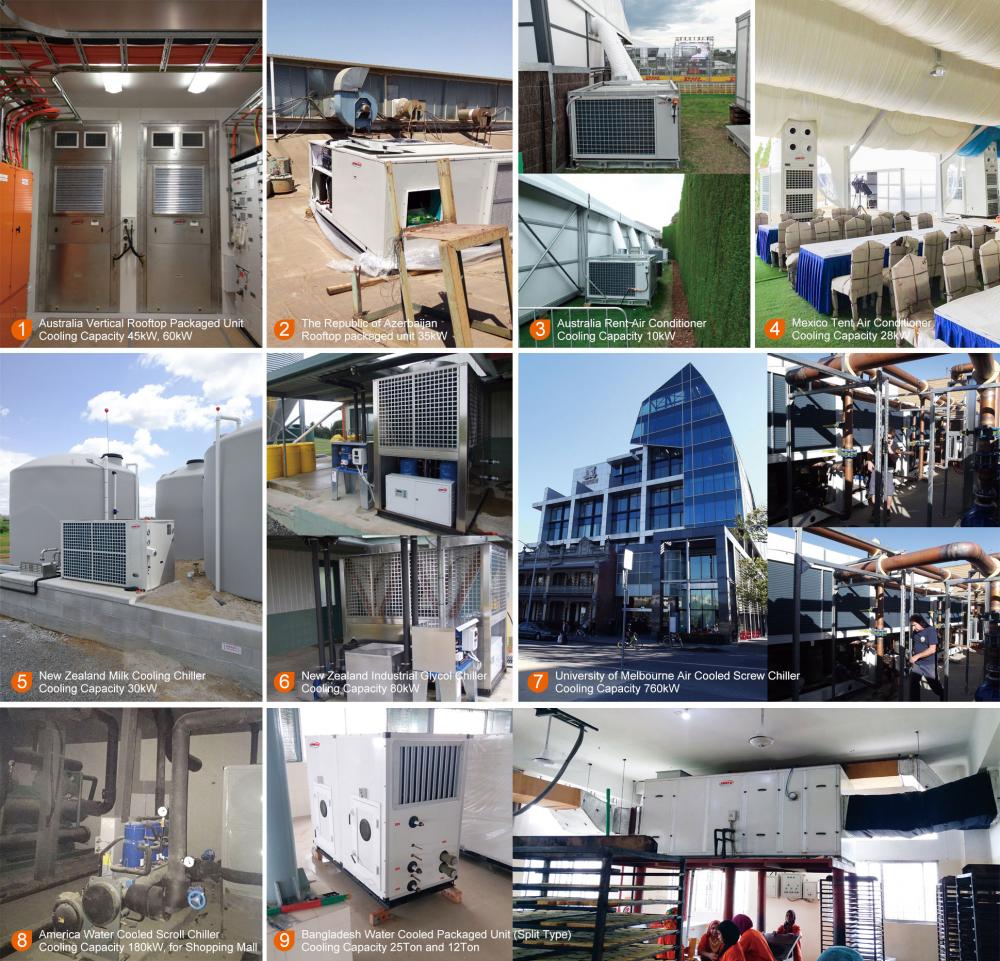

Amrta Industrial Centrifugal Water Cooled Chiller has done successful solutions to energy saving for hotel hot water system by applying our heat recovery and hot water units. Industrial Water Chiller for plastic extruder and injection machine is one of our major chiller business. Our Screw Water Chiller with built-in single or double circulating water pumps and insulated water tank are widely applied in industries for cooling of laser generator, welding electrodes, cutting machines, electric spark machine, extrusion process, hydraulic System, electroplating, ultrasonic cleaning, Ion plating film, electronic facility, electrical appliance components, compressed gas dehumidification, dairy and beverage cooling processing, pharmaceutical and biological product, medical equipment, glass coating, tempered glass and cultivation sea food.

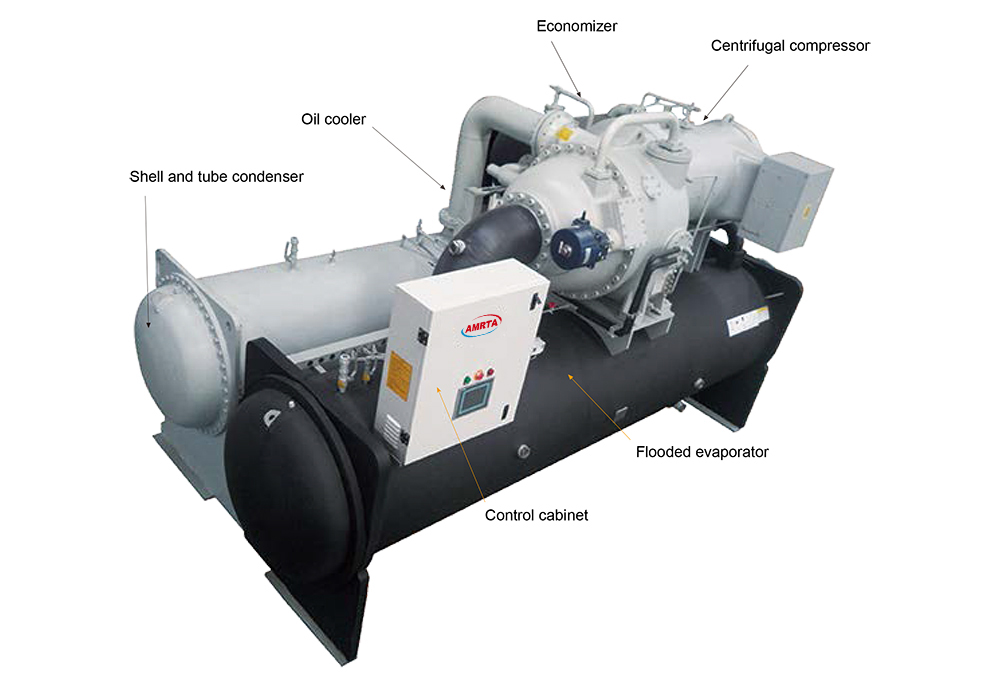

Unit adopts two-stage centrifugal compressor with high energy efficiency.

Three-phase bipolar squirrel cage induction motor.

Y- △ start, direct start or soft start.

High efficiency two-stage compression and economizer design.

Protection level - IP54.

High-strength aluminum enclosed impeller. Enclosed impeller is more efficient than open type.

The unit supply voltage is optional:

380V/6000V/10000V

Select high voltage to reduce initial investment; require no transformer; save cable cost; save electrical equipment installation cost and machine room investment.

The unit adopts SIEMENS microcomputer intelligent control

Simple operation, complete protection, English interface, real-time monitoring, clear display of all running data, extremely convenient operation.

Capacity adjustment is wide with 10~100% stepless capacity adjustment.

It has perfect protection functions, such as power protection, high voltage protection, low voltage protection, oil temperature protection, etc., which makes the unit running more reliable.

The Screw Type Industrial Chiller has advanced multiple anti-surge function, and adopts the combination of prevention, control and alarm, so that the unit can meet customers' demand for cooling capacity in a safe range.

Visually display switch state, analog state, input, alarm and fault, etc.

Diversified unit throttling control programs

According to different working conditions and requirements, three throttling programs are available:

orifice plate, orifice plate and solenoid valve in parallel connection, orifice plate and electric control valve in parallel connection.

Orifice plate+electric control valve in parallel connection is the most accurate for throttling control but the cost is higher, so it can be as an optional program.

Each set of orifice plates is customized according to centrifuge and unit performance to achieve the best matching with unit performance.

Since orifice plate has no any movable parts, its reliability is better than various throttle valves by mechanical transmission.

The unit adopts liquid level intelligent control

Adopt static capacitance continuous liquid level meter or floating ball level meter to control the liquid level of condenser so as to make the unit running more reliable and accurate.

Separate oil return system

The oil pump is built in compressor with separate oil return and cooling system, making the compressor lubrication more reliable.

The Water Chiller adopts injection pump as oil return component, and uses high pressure gas as power to complete oil return function at low pressure side.

The unit adopts environmental refrigerant R134a

R134a is HFC working medium, which is an internationally recognized environmental refrigerant.

Compact design, small area, low noise

Compressor

The compressor adopts imported famous brand two-stage centrifugal compressor

Three-phase bipolar squirrel cage induction motor.

Y- △ start, direct start or soft start.

Design of high efficiency two-stage compression and economizer.

Protection level - IP54.

High-strength aluminum enclosed impeller.

High speed shaft is made of high strength alloy.

Under normal operation, the bearing life is up to 50000 hours.

It is the most efficient in HFC-134a centrifugal compressors.

Heat exchanger

The evaporator is flooded or falling-film type, and the design pressure at refrigerant side is 0.9MPa.

Adopt high efficiency heat exchange tube as well as external fin and internal thread to be fixed on end plate by mechanical piping expansion. When the standard configuration is 1.0MPa, the water side is 2-3 tube pass, and the test pressure at water side is 1.25 times of the maximum working pressure.

The design pressure at refrigerant side is 1.3MPa. Adopt high-efficient heat exchange tube as well as external fin and internal thread to be fixed on end plate by mechanical piping expansion. The test pressure at water side is 1.25 times of the maximum working pressure.

The high efficiency economizer has a carbon steel cylinder body, and the internal design is to prevent the liquid refrigerant from entering compressor, and it has also improved the efficiency of the unit by adding air in the course of compression.

The oil cooler adopts high efficiency plate heat exchanger to control oil temperature, so as to achieve the purpose of cooling the compressor lubricating oil.

Technical Data

Unit Model ACP350WDA ACP400WDA ACP450WDA ACP500WDA ACP550WDA ACP600WDA Cooling

Capacity RT 350 400 450 500 550 600 KW 1231 1407 1583 1759 1934 2110 104kca/h 106 121 136 151 166 181 Electric Motor Power KW 208 242 277 306 334 340 Power Supply / 380-3ph-50Hz Cooling Mode / Refrigerant Spray Cooling Performance Factor COP KW/KW 5.92 5.81 5.72 5.75 5.8 6.2 Refrigerant R134a Evaporator Cold Water Flow m3/h 212 242 272 302 333 363 Cold Water Pressure Drop kPa 65 84 82 86 87 84 Number of Pass / 2 Cold Water Inlet/Outlet Temperature °C 12/7 Connection Diameter DN 200 200 200 200 200 200 Condenser Cooling Water Flow m3/h 265 302 340 378 416 454 Cooling Water Pressure Drop kPa 70 85 87 84 89 87 Number of Pass / 2 Cooling Water Inlet/Outlet Temperature °C 30/35 Connection Diameter DN 200 200 200 200 200 200 Weight Transport Weight kg 5700 7575 7850 8100 8850 9150 Operating Weight kg 6200 8712 9027 9315 10188 10605 Dimension Length(A) mm 3850 4675 4675 4770 4770 4770 Width(B) mm 1810 1850 1850 2270 2270 2270 Height(C) mm 2000 2050 2050 2400 2400 2400

Unit Model ACP650WDA ACP700WDA ACP750WDA ACP800WDA ACP850WDA ACP900WDA Cooling

Capacity RT 650 700 750 800 850 900 KW 2286 2462 2638 2814 2989 3165 104kca/h 197 212 227 242 257 272

Electric Motor Power KW 369 400 425 452 483 513 Power Supply / 380-3ph-50Hz 6000/10000V-3ph-50Hz Cooling Mode / Refrigerant Spray Cooling Performance Factor COP KW/KW 6.19 6.16 6.21 6.22 6.19 6.17 Refrigerant R134a Evaporator Cold Water Flow m3/h 393 423 454 484 514 544 Cold Water Pressure Drop kPa 81 81 87 88 87 87 Number of Pass / 2 Cold Water Inlet/Outlet Temperature °C 12/7 Connection Diameter DN 200 250 250 300 300 300 Condenser Cooling Water Flow m3/h 491 529 567 605 643 681 Cooling Water Pressure Drop kPa 80 77 84 88 85 84 Number of Pass / 2 Cooling Water Inlet/Outlet Temperature °C 30/35 Connection Diameter DN 200 250 250 300 300 300 Weight Transport Weight kg 11350 11400 11400 13650 13650 14950 Operating Weight kg 13120 13250 13250 15700 15700 17580 Dimension Length(A) mm 4770 5100 5100 5100 5100 5100 Width(B) mm 2270 2400 2400 2400 2400 2400 Height(C) mm 2400 2600 2600 2600 2600 2600

Unit Model ACP950WDA ACP1000WDA ACP1100WDA ACP1200WDA ACP1300WDA ACP1400WDA Cooling Capacity RT 950 1000 1100 1200 1300 1400 KW 3341 3517 3869 4220 4572 4924 104kca/h 287 302 333 363 393 423 Electric Motor Power KW 536 568 626 683 735 793 Power Supply / 6000/10000V-3ph-50Hz Cooling Mode / Refrigerant Spray Cooling Performance Factor COP KW/KW 6.23 6.19 6.18 6.18 6.22 6.21 Refrigerant R134a Evaporator Cold Water Flow m3/h 575 605 665 726 786 847 Cold Water Pressure Drop kPa 80 89 87 95 100 103 Number of Pass / 2 Cold Water Inlet/Outlet Temperature °C 12/7 Connection Diameter DN 300 300 350 350 350 350 Condenser Cooling Water Flow m3/h 718 756 832 907 983 1059 Cooling Water Pressure Drop kPa 82 94 89 95 92 95 Number of Pass / 2 Cooling Water Inlet/Outlet Temperature °C 30/35 Connection Diameter DN 300 300 350 350 350 350 Weight Transport Weight kg 14950 15050 15320 15320 18800 18950 Operating Weight kg 17580 17750 18400 18400 20660 21450 Dimension Length(A) mm 5200 5200 5200 5200 5200 5560 Width(B) mm 2650 2650 2650 2650 2650 2950 Height(C) mm 2800 2800 2800 2800 2800 2960

Notes: Unit Model ACP1500WDA ACP1600WDA ACP1700WDA ACP1800WDA ACP1900WDA ACP2000WDA Cooling Capacity RT 1500 1600 1700 1800 1900 2000 KW 5276 5627 5979 6331 6682 7034 104kca/h 454 484 514 544 575 605 Electric Motor Power KW 852 905 963 1026 1074 1136 Power Supply / 6000/10000V-3ph-50Hz Cooling Mode / Refrigerant Spray Cooling Performance Factor COP KW/KW 6.19 6.22 6.21 6.17 6.22 6.19 Refrigerant R134a Evaporator Cold Water Flow m3/h 907 968 1028 1089 1149 1210 Cold Water Pressure Drop kPa 98 100 103 105 105 102 Number of Pass / 2 Cold Water Inlet/Outlet Temperature °C 12/7 Connection Diameter DN 350 400 400 400 400 400 Condenser Cooling Water Flow m3/h 1134 1210 1285 1361 1437 1512 Cooling Water Pressure Drop kPa 96 92 95 89 89 92 Number of Pass / 2 Cooling Water Inlet/Outlet Temperature °C 30/35 Connection Diameter DN 350 400 400 400 400 400 Weight Transport Weight kg 19250 24600 25655 28750 29450 29450 Operating Weight kg 21550 27755 29503 30700 32050 32050 Dimension Length(A) mm 5560 5560 5560 5560 6150 6150 Width(B) mm 2950 2950 2950 2950 3100 3100 Height(C) mm 2960 2960 2960 2960 3150 3150

1.Nominal condition: chilled water inlet/outlet temperature of 12°C/7°C, and cooling water inlet/outlet temperature of 30°C/35°C.

2.Fouling factor of evaporator is 0.018m2°C/kw, and fouling factor of condenser is 0.044m2°C/kw.

3.This parameter is subject to change without notice.

Product Series

Project

Why Choose Amrta?

Product Categories : Water Chiller > Water Cooled Chiller

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.