Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: RTU12~RTU300

Brand: Amrta or OEM

Type: Chiller

Air Tube Material: Galvanized Sheet

Corrosion Durability: Higher

Operating Voltage: 380/400 VAC

Noise Level: Low

Mounting: Floor Standing

Lifetime: 15~20 years

Certification: CE

Condition: New

Application Fields: Mechanical Engineering, School, Airport, Shopping Mall, Industrial Buildings

Refrigerant: R410A/R407c/R134A/R22

Cooling Capacity: 12kw-300kw

Electric Parts: Schneider Brand

Power Supply: 380~415V, 440~460V, 50HZ/60HZ

Compressor Brand: Copeland/Danfoss/Panasonic/Daikin

Refrigerant Valves: Emerson/Danfoss Brand

Controller: Syslab Brand Or Siemens PLC Controller(optional)

Energy Recovery: Optional

Gas Burner: Optional

Packaging: Plywood Casing or standard package suitable for sea and air transport

Productivity: 6000PCS/Year

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 500PCS/Month

HS Code: 8418612090

Port: Qingdao,Shandong,China

Payment Type: L/C,T/T,Western Union

Incoterm: FOB,CFR,CIF

Low installation lost

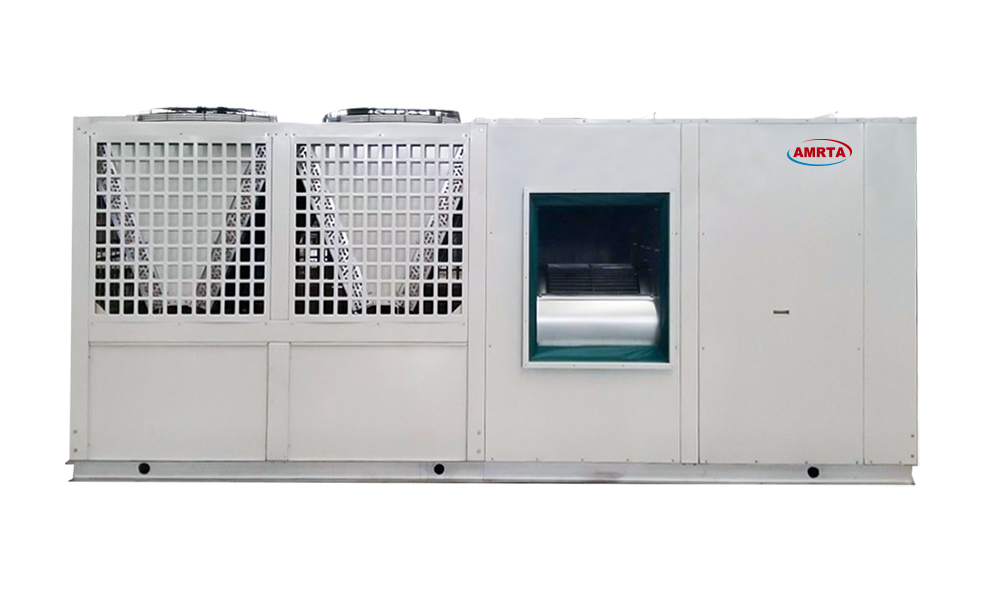

01.Rooftop Unit Air Conditioning Delars are completely wired, charged with R-410A and tested prior to shipment. Unique test stations using a new state of the art computerized process system are used to insure product quality

02.Commercial HVAC Air Conditioning Rooftop. Refrigerant charge and component part numbers are verified via computers at assembly. Vital run test statistics such as system pressure, moto currents, air velocity and temperature, unit vibration, and gas system safeties are monitored and recorded by the system to insure unit performance.

03.Central Air Conditiong.Equal size, side supply and return duct connections allows easy hook-up of ducts to match low crawl spaces without transition pieces.

Characteristics

01.Structure. Panels and frame are made from galvanized steel protected with polyester powder painting to ensure total resistance to atmospheric agents.Direct expansion coils with condensate drain tray.

02. Hermetic compressor. High efficiency scroll compressor for the whole range, with built-in thermal overload cut-out and crankcase heater, mounted on rubber vibration dampers. Ripple type acoustic insulation for compressor section, and thermal insulation for coil and fan section, low noise.

03.Centrifugal fan. Forward curve centrifugal fans for air treatment section and axial fans for condensation section. Front, side and underside air discharge of the treatment unit. High external pressure, long air supply distance.

04. Electric panel. Electric panel consists of breakers and contactors for compressors and fan motors, phase sequence relay and other necessary protection devices for the main components.

Timing on/off

Economizer with fresh, return air dampers and fresh air hood

Free cooling function for low ambient temperature

Low ambient control device for operation of outdoor units at ambient temperatures from less than 20°C down to -10°CG4 filter, plate and bag filter

07. Economizer and Free Cooling.

It is one of the most important features of this rooftop as it maximise seasonal efficiency by reducing the use of thermodynamic cooling in mid season.

Thermodynamic cooling can be replaced by Free Cooling when outdoor temperature is below the building set point saving up to 15% on annual energy consumption.Rooftop units are supplied with economizer and fresh air hood to improve comfort through better fresh air management and allow energy savings with free cooling.

Interlocked to run when return air dampers are being closed and supply air blower is in operation. The extraction fans run when outdoor air dampers are at least 50% open (adjustable). It is also overload protected. A gravity exhaust damper is supplied with this option to prevent air from entering the unit during shutdown. The power exhaust fans have been size to exhaust 50% of the nominal air flow of the Rooftop Packaged Unit.

Technical Data

| Model | RTU45 | RTU50 | RTU60 | RTU75 | RTU90 | RTU105 | ||

| Cooling capacity | kW | 44.5 | 50 | 60 | 70 | 90 | 105 | |

| Heating capacity | kW | 48.7 | 54.3 | 64 | 75.4 | 96.2 | 113.2 | |

| Power supply | 380V / 3Ph / 50HZA | |||||||

| Cooling power input | kW | 17 | 19.5 | 22.8 | 26.7 | 32.9 | 39.7 | |

| Heating power input | kW | 15.6 | 18 | 21 | 24.8 | 30.4 | 36.7 | |

| Start current | A | 168 | 186 | 175 | 199 | 197 | 266 | |

| Working current in cooling | A | 31.7 | 35.6 | 39.9 | 48.3 | 61 | 70.6 | |

| Working current in heating | A | 29.9 | 33.5 | 37.5 | 45.4 | 57.3 | 66.3 | |

| Throttle methods | Thermal expansion valve | |||||||

| Circuits | 2 | 2 | 2 | 2 | 3 | 3 | ||

| Refrigerant | R410A | |||||||

| Compressor | Type | Scroll type 380V / 3Ph / 50HZA | ||||||

| Qty | 2 | 2 | 2 | 2 | 3 | 3 | ||

| Condenser side | ||||||||

| Condenser | Type | Al+copper tube | ||||||

| Axial fan | Qty | 1 | 1 | 1 | 1 | 2 | 2 | |

| Drive | Direct drive | |||||||

| Motor power | kW | 0.25 | 0.37 | 0.37 | 0.55 | 0.75 | 0.75 | |

| Air flow | m3 /h | 4600 | 7800 | 7800 | 9000 | 12600 | 12600 | |

| Evaporator side | ||||||||

| Evaporator | Type | Al+copper tube | ||||||

| Centrifugal fan | Qty | 1 | 1 | 1 | 1 | 1 | 1 | |

| Motor power | kW | 3 | 3 | 4 | 4 | 5.5 | 5.5 | |

| Air flow | m3 /h | 7600 | 8500 | 10900 | 12500 | 16000 | 19500 | |

| Drive | Direct drive | Belt drive | ||||||

| External static pressure(Pa) | 250 | 250 | 300 | 300 | 300 | 300 | ||

| Filter | Aluminum frame filter G3 | |||||||

| Noise level dB(A) | 73 | 73 | 73 | 75 | 74 | 75 | ||

| Dimension | L | mm | 2268 | 2268 | 2298 | 2298 | 2878 | 2878 |

| W | mm | 1440 | 1440 | 1650 | 1650 | 2140 | 2270 | |

| H | mm | 1167 | 1167 | 1400 | 1400 | 1964 | 1964 | |

| Weight | kg | 750 | 770 | 830 | 860 | 1160 | 1350 | |

Product Pictures

Overseas Simple Projects

Main Spare Parts

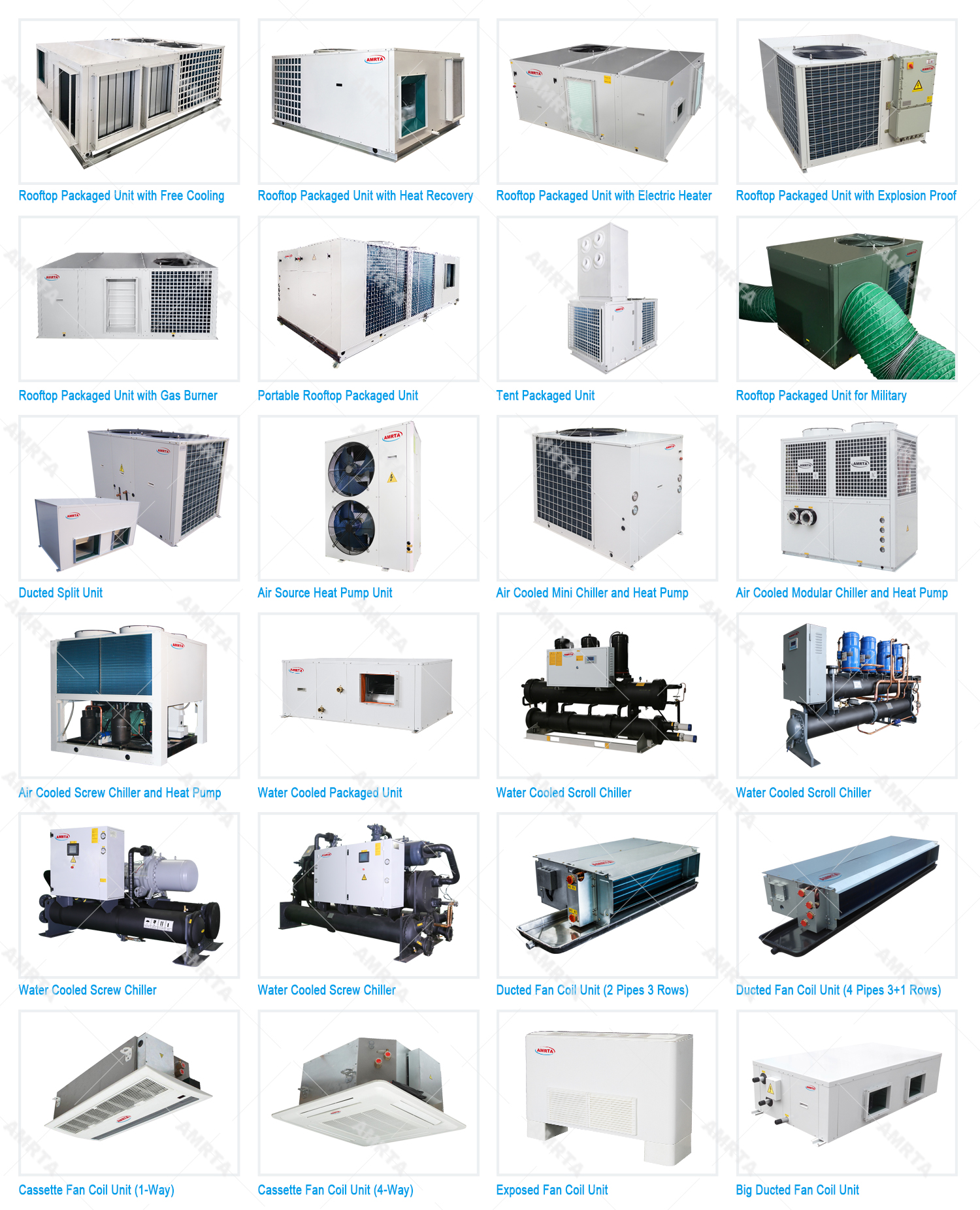

We are MANUFACTURER of Central Air Conditioner. Our units cover Rooftop packaged unit(10kW-240kW), Air Cooled Water Chiller(8kW-1200kW), Geothermal Heat Pump(10kW-2500kW), VRF system and Fan Coil unit etc. All of our products are qualified with CE certificate.

Our Product Ranges

Product Categories : Rooftop Packaged Unit > Rooftop Packaged Unit With Gas Burner

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.