Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: AW()

Brand: Amrta or OEM

Applicable Industry: Hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food &Amp; Beverage Factory, Farms, Restaurant, Retail, Food Shop, Printing Shops, Construction Works, Energy &Amp; Mining, Food &Amp; Beverage Shops, Advertising Company

Status: New

Species: Chiller

Place Of Origin: China

Operating Voltage: 380/400 Vac

Installation Method: Floor Standing

Certification: Ce

Warranty Period: 1 Year

Core Selling Point: Sustainable, Automatic, High-Accuracy, Competitive Price, Low Maintenance Cost, Easy To Operate, High Safety Level, High Productivity, Famous Brand Low Voltage Components, Remote Monitoring, Long Service Life, Remote Control, Patented Product, Energy Saving, Low Noise Level, Famous Brand Motor, Famous Brand Plc, Voice Navigation, Accurate Temperature Control

Core Component Warranty Period: 1 Year

Type: Cooling Only With Electric Heater/Cooling Only/Heat Pump

Cooling Water: Industrial Water

System Type: Closed System

Noise Level: Ultra Low

Certification: CE

Condition: New

Compressor Brand: Copeland / Danfoss / Daikin / Panasonic

Refrigerant: R410A / R407c / R134A / R22

Evaporator: Plate / Shell And Tube

Power Supply: 380-415V, 440-460V, 50HZ/60HZ

Compressor Qty/Circult: 2/3/4

Casing(Optional): Stainless Steel 304/316

Application Fields: Hotels, Apartments, Restaurants, Office

Running Condition: Low Ambient Temperature -20degree C

Packaging: Plastic Film Wrapped

Productivity: 7000sets/year

Transportation: Ocean,Air

Place of Origin: China

Supply Ability: 400PCS / Month

Certificate: CE

HS Code: 8418692090

Port: Qingdao

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

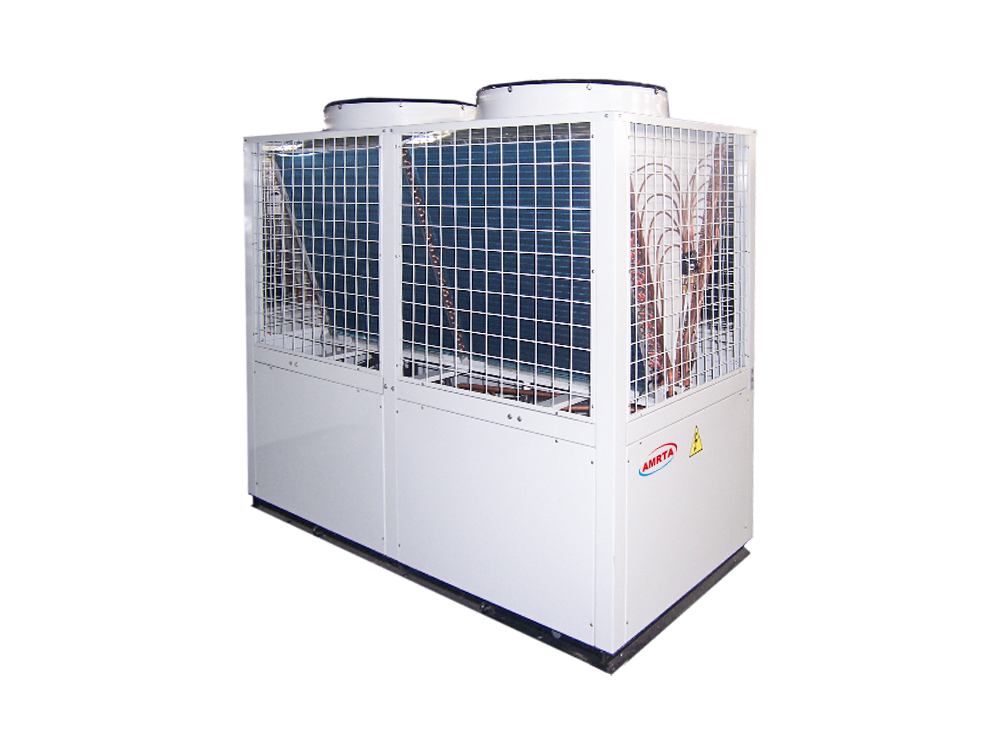

Amrta Industrial Modular Water Chiller is suitable for a wide range of applications. With the additional advantage of being able to reverse cycle they can be used for cooling in summer and heating in winter. Amrta Scroll Water Chiller can be installed in new builds or retrofitted to existing buildings such as hotels, apartments, restaurants, office buildings, shopping malls, theaters, gyms, workshops, hospitals and any other place where cooling or heating is required. Amrta Air Cooled Water Chiller don`t restrict the length of your pipe runs like other Air Conditioning systems do. By using pumped water you can transfer heat over much greater distances. You also have the advantage of not having to worry about your compressors being starved of oil due to poor design or installation.

Application areas

● Offices, Hotels, Hospitals, Industry

● Administration

● Light commercial and residential buildings

Why this choice?

● Very high efficiency with R410A

● Very low noise operation

● R410A scroll compressors

● Advanced control

● Water Chiller unit with pump and optional buffer tank

● Very compact for outdoor or indoor installation

Scroll water chiller characteristics

The master module can work independently or together with up to 16 slave modules.

Modular Water Chiller units with V type heat exchanger: panels, frame and base are made from galvanized steel protected with polyester powder painting to ensure total resistance to atmospheric agents.

3-phase scroll type compressor, with builtin thermal overload cut-out and crankcase heater, mounted on rubber vibration dampers.

External rotor type axial fans, equipped with three phase direct drive motors, low noise 8 poles, protection level IP54, provided with a protective outlet grille.

Evaporator built with high efficiency shell and tube type heat exchanger, factory insulated with flexible close cell material.

Condenser built with seamless copper tubes mechanically expanded into blue hydrophilic aluminum fins.

Refrigerant circuit complete with charge valves, filter drier, sight glass, gas-liquid separator, thermostatic expansion valve, high & low pressure switch. The Heat Pump System unit is completed also with 4-way valve, liquid receiver and one way valve.

Hydraulic circuit built with galvanized pipe, complete with water discharge connection for tube in tube heat exchanger and flange type hydraulic connectors in two directions easy for connections from both sides of the units.

Electric panel consist of:

Compressor contactor, fan motor contactor, compressor protection breaker, fan protection breaker, phase sequence relay and microprocessor with function display (display only for master/packaged unit)

Automatic operation dramatically reducing maintenance cost thanks to reliable microprocessor system.

Optional

Paddle flow switch;

Metallic filter for hydraulic circuit;

Water pump;

Rubber antivibration mounting;

Heat recovery functions.

Water chiller technical data

| Model AW | 60 | 100 | 130 | 200 | 260 | ||

| Cooling capacity* | kW | 65 | 97.5 | 130 | 195 | 260 | |

| Cooling power input | kW | 20.8 | 31.4 | 42.1 | 63.6 | 84.2 | |

| Heating capacity** | kW | 68 | 102 | 136 | 204 | 272 | |

| Heating power input | kW | 20.2 | 30.6 | 41 | 61.2 | 82 | |

| Max Input Power | kW | 24 | 35.7 | 47.7 | 71.4 | 95.4 | |

| Max Input current | A | 50 | 74 | 97 | 148 | 194 | |

| Cooling Running Current | A | 46 | 68 | 89 | 136 | 178 | |

| Start-Up Current | A | 167 | 187 | 206 | 374 | 412 | |

| Compressor | |||||||

| Power supply | / | 380/3/50 | |||||

| Brand/Type | / | Daikin/Scroll | |||||

| Refrigerant | / | R410a | |||||

| Qty/refrigerant circuit | Nr. | 2 | 3 | 4 | 6 | 8 | |

| Cooling power input* | kW | 2*9.4 | 3*9.63 | 4*9.77 | 6*9.63 | 8*9.77 | |

| Heating power input** | kW | 2*9.1 | 3*9.36 | 4*9.5 | 6*9.36 | 8*9.5 | |

| Energy adjustment | % | 0-25-50-75-100 | |||||

| Axial fan | |||||||

| Quantity | Nr. | 2 | 2 | 2 | 4 | 4 | |

| Power input | kW | 2 | 2.5 | 3 | 5 | 6 | |

| Airflow | m3/h | 24000 | 36000 | 48000 | 72000 | 96000 | |

| Evaporator | |||||||

| Type | / | Shell and tube heat exchanger | |||||

| Water flow when cooling | m3/h | 11.2 | 16.8 | 22.4 | 33.6 | 44.8 | |

| Water flow when heating | m3/h | 11.7 | 17.6 | 23.4 | 35.1 | 46.8 | |

| Water side pressure drop *** | kPa | 46 | 52 | 55 | 52 | 55 | |

| Water connection size | DN | 50 | 50 | 65 | 2x50 | 2x65 | |

| Noise level*** | dB(A) | 70 | 72 | 72 | 74 | 75 | |

| Dimensions | |||||||

| V type coil | Length | mm | 2000 | 2207 | 2207 | 2207 | 2207 |

| Width | mm | 1060 | 1300 | 1300 | 2207 | 2207 | |

| Height | mm | 1957 | 2076 | 2076 | 2096 | 2096 | |

| Net weight | kg | 620 | 1060 | 1120 | 2160 | 2280 | |

| Working weight | kg | 635 | 1090 | 1155 | 2220 | 2350 | |

**** Sound pressure measured at a distance of 1 m and a height of 1.5 m above the ground in a dear field.

Air cooled water chiller ordering process

Product Categories : Water Chiller > Modular Water Chiller

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.